|

Henan Zhongcheng Machinery Co,Ltd

|

Gold Index: 18883

You are here: home > High energy efficiency Mineral Screening Equipment popular in Asia

High energy efficiency Mineral Screening Equipment popular in Asia

| Price: | 1000.0~10000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GZD-850*3000

Production Capacity:

100sets/mouth

Delivery Date:

7~15 days after payment

Type:

Sand Washer

Warranty:

1 year

Means of Transport:

Ocean

Packing:

Export standard

Application:

Ore

Brand Name:

ZHONGCHENG

Color:

discussion

1 High-efficient stone jaw machine

2 Deep broken cavity

3 Save energy 15% -30%

4 Low noise and less dust

5 ISO:CE

High energy efficiency Mineral Screening Equipment popular in Asia

contact: sheila +86-13526578789

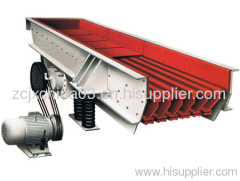

1. Introduction of YK Circle Vibrating Screen:

This series of vibrating screen do circular motion, it is a new multilayer, high-efficient vibrating screen. Circular vibrating screen uses the eccentric shaft vibration exciter and partial block to adjust the amplitude, long materials streaming line, different screening specifications, it is with reliable structure ,strong vibrating force, and high screening efficiency, low noise, durable, easy maintenance, use safety, etc. The vibrating screen widely used in mining, building materials, transportation, energy and chemical industry.

2. Primary structure of vibrating screen:

Vibrating screen consists of eccentric vibration exciter, screen box, motor, bed frame and bearing set.

3. Vibrating screen work principle:

The motor with vee belt makes the eccentric of the activator start high speed rotation. Operation of eccentric block generates a lot of centrifugal force, Stimulate screen box form certain amplitude? Circular motion, material on the tilted screen surface throws the continuous movement. The grain is less than the screen hole through sieve during materials and sieving meeting, so as to realize the particle grading.

4. Circular vibrating screen Features:

(1)Simple and dependable Eccentric type system.

(2)High screening capacity and High durability.

(3)No transmission of screen panels.

(4)Ready changing of screen plates.

(5)Rigid and vibrating resistance screen body.

5. Vibrating screen's use and maintenance:

Vibrating starts up when sieve surface has no material, try to avoid taking materials to start. Vibrating screen should operate smoothly before feeding. If it worked abnormally, shut down and check carefully, find out the reasons, trouble-shooting.

6. Technical parameters of circle vibrating screen:

Type | Screen area | Siev pore size(mm) | Feed size(mm) | Production capacity(t/h) | Motor power(kw) | Weight(kg) |

2YK1235 | 2 | 5-120 | <=400 | 60-120 | 5.5 | 3600 |

2YK1545 | 2 | 5-150 | <=400 | 110-360 | 15 | 6400 |

3YK1545 | 3 | 5-150 | <=400 | 110-360 | 15 | 5800 |

3YK1548 | 3 | 5-150 | <=400 | 120-385 | 15 | 6600 |

4YK1548 | 4 | 5-150 | <=400 | 120-385 | 15 | 7200 |

2YK1854 | 2 | 5-200 | <=400 | 200-450 | 18.5 | 8150 |

3YK1854 | 3 | 5-200 | <=400 | 200-450 | 18.5 | 8850 |

4YK1854 | 4 | 5-200 | <=400 | 250-600 | 18.5 | 9550 |

3YK1860 | 3 | 5-200 | <=400 | 250-600 | 22 | 9100 |

4YK1860 | 4 | 5-200 | <=400 | 300-750 | 22 | 9800 |

3YK2060 | 3 | 6-200 | <=400 | 300-750 | 37 | 10800 |

4YK2060 | 4 | 6-200 | <=400 | 400-850 | 37 | 11800 |

3YK2460 | 3 | 6-200 | <=400 | 400-850 | 45 | 16600 |

4YK2460 | 4 | 6-200 | <=400 | 400-850 | 45 | 17000 |

Service Promise

Before-sale services: We guide customers to choose the best applicable device type and provide the advanced, energy-saving and practical technological process, and also we are responsible for the site planning and design.

On-sale services:products must be inspected strictly before sell, customers are invited to simulate and test machine on-the-spot and raise objections. We will organize delivery according to the clauses stipulated in the contract.

After-sale services:Our Company will send professional engineers to guide installation, debugging and training operators until customers are fully satisfied. Moreover, we can design and manufacture products according to customers' specific requirement.

Related Search

High Efficiency Machine

High Efficiency Filter

High Efficiency Motor

Energy Equipment

Mineral Processing Equipment

High Power Energy Saving Lamp

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Henan Zhongcheng Machinery Co,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

.gif)