|

Henan Zhongcheng Machinery Co,Ltd

|

Gold Index: 18883

You are here: home > High productivity magnet separator in industry

High productivity magnet separator in industry

| Price: | 1000.0~10000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

CTB600*900

Production Capacity:

100sets/mouth

Delivery Date:

7~15 days after payment

Type:

Separator

Warranty:

1 year

Means of Transport:

Ocean,Land

Packing:

Export standard

Application:

Ore

Brand Name:

ZHONGCHENG

Detailed Product Description

1. Stable and long span life

2. Easy to adjust

3. Reliable operation.

4. Easy maintenance.

5. No polluti

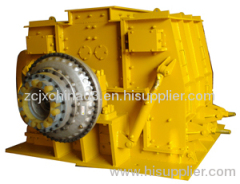

High productivity magnet separator in industry

1. Introduction of magnetic separator:

Magnetic separator applies to wet magnetic separation of materials below 3mm such as the magnetite, pyrrhotite, roasted ore, ilmenite. also used for coal, non-metallic minerals, building materials' remove working.

2. Structural characteristics of magnetic separator:

Magnetic line of the magnetic separator uses high quality ferrite materials or compound with rare-earth magnet, the average magnetic induction is 100--600mt,we can provide downstream, semi-current, counter-current, a number of different forms magnetic separator according to the users' need. this magnetic separator has simple structure, convenient operation, capacity, easy maintenance etc advantages.

3. Wet permanent magnetic separator:

Magnetic separator is ely used in iron ore concentrator, it is applied in strong magnetic minerals.

It can be divided into downstream, semi-current, counter-current three types according to slot structure.

It except used as magnetic equipment in the magnetic separation plant, it also used as concentrated equipments before filter in the recent years. to replace the magnetic dehydration trough.

4. Strong magnetic field separator:

Strong magnetic field magnetic separator has many types, it can divided into dry and wet according to the work condition. by the magnetic source it is divided into electromagnetic and permanent magnet. according to equipment structure it can divided into disc, roller, flat ring, ring-li, roller sensor etc.

5. Technical parametes of magneitic separator:

Specification and Type | Magnetic Field Strength(Oe) | Handling Capacity (t/h) | Motor Power(kw) | Machine Weight (kg) |

CTB600×900 | 1450 | 8-15 | 1.1 | 910 |

CTB600×1800 | 1500 | 15-25 | 2.2 | 1340 |

CTB750×1200 | 1550 | 25-30 | 2.8 | 1490 |

CTB750×1800 | 1550 | 30-45 | 3 | 2050 |

CTB900×1800 | 1650 | 35-60 | 4 | 3000 |

CTB1050×2400 | 1650 | 60-95 | 5.5 | 5020 |

CTB1200×3000 | 1650 | 80-150 | 7.5 | 7800 |

CTB1500×3000 | 1650 | 120-200 | 11 | 9600 |

Service Promise

Before-sale services: We guide customers to choose the best applicable device type and provide the advanced, energy-saving and practical technological process, and also we are responsible for the site planning and design.

On-sale services:products must be inspected strictly before sell, customers are invited to simulate and test machine on-the-spot and raise objections. We will organize delivery according to the clauses stipulated in the contract.

After-sale services:Our Company will send professional engineers to guide installation, debugging and training operators until customers are fully satisfied. Moreover, we can design and manufacture products according to customers’ specific requirement.

Related Search

Wet Magnet Separator

Separator

Industry Pump

Industry Air Compressor

Magnetic Separator

Water Separator

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Henan Zhongcheng Machinery Co,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

.gif)