|

Henan Zhongcheng Machinery Co,Ltd

|

Gold Index: 18883

You are here: home > Construction Machinery Hollow Block Making Machine

Construction Machinery Hollow Block Making Machine

| Price: | 1000.0~10000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

QYT8-15

Production Capacity:

100sets/mouth

Delivery Date:

7~15 days after payment

Type:

Belt Conveyor

Warranty:

1 year

Means of Transport:

Ocean,Land

Packing:

Export standard

Application:

Ore

Brand Name:

ZHONGCHENG

Detailed Product Description

1. Stable and long span life

2. Easy to adjust

3. Reliable operation.

4. Easy maintenance.

5. No polluti

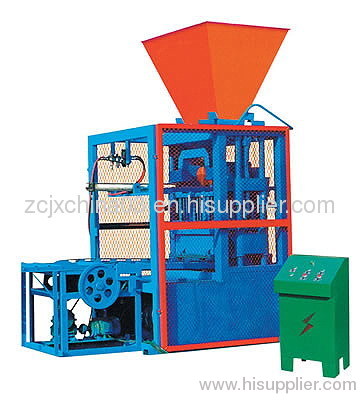

Construction Machinery Hollow Block Making Machine

Contact with +0086-13526578789

1.Product description of hollow block making machine:

1.Electrical System use imported color touch screen and programmable Logic Controller PLC, it equipped with data input and output devices, control system includes security logic control and fault diagnosis system.

2.The body using high-precision, high-strength castings special welding technology and materials make,rigid, and earthquake-resistant, long life.

3.Super-load design, refinement of movement, mandatory feed,little noise.

4. It uses advanced compulsory feed method, So it has the characteristics of raw materials wide applicability. rapid and uniform feed, high yield, it is the leading of the environmental performance in domestic models.

5.A multi-purpose machine,it can produce different specifications brick, hollow block, curb stone, brick roads and tree planting grass brick, slope protection brick and other cement products, With fabric device can Produce color brick road etc.

main technical performances and parameters

Super steel structure design,widely use imported original,to make the body more stable and reliable. Efficient, super excitation system design, Using the pressure and flow which controlled by computer hydraulic system. realize the vertical synchronous vibration, frequency conversion, brake.two sides synthesis output,it transport the vibration to the every part of mode box efficiently and balancely.

2.Constructure of hollow block making machine:

Whole machine is using PLC system, computer interface operation, it can be achieved random signal analysis, fault diagnosis and parameter setting, to ensure the best effectiveness of the machine.

Equipped with special hydraulic code machine, it can easily realize big yield, automation production, save a lot of investment of human, maintenance yard and cash. semi-enclosed compulsory cloth system, make the feeder more uniform and faster.

3.Technical parameters of hollow block making machine:

forming blocks | molding cycle | theory output | host power | whole weight | outline size | pallet size |

390X190X190 8pieces/modle 15360pieces/shift 240×115×90 21pieces/module 40320pieces/shift 240×115X53 42pcs/module 80640pieces/shift | 15s | about 80640pieces/shift Standard brick | 34.5KW | 11.6T | 7200× 2100× 2825mm | 920× 850× 40mm |

4.Service Promise

Before-sale services:We guide customers to choose the best appliable device type; provide the advanced,energy-saving and practical technological

process,and we are responsible for the site planing and design.

Sale services: products must be inspected Strictly before selling;customers are invited to simulate and test machine on-the-spot and raise objections;in accordance with the agreements stipulated in the contract,we will organize delivery.

After-sale services:Our company will send professional engineers to guide device installation,debugging and training operators until customers are fully satisfied.

Moreover,we will design and manufacture products,according to the special requirements of customers

Solemn Promise:The quality guarantee period for machines is one year except the wearing parts.

Warm tips: the prices in the web only for reference, according to raw material price fluctuations, Specific price is subject to the calling.

Related Search

Hollow Block Making Machinery

Block Making Machinery

Block Making Machine

Concrete Block Making Machine

Hollow Block

Construction Machinery

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Henan Zhongcheng Machinery Co,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

.gif)