|

Henan Zhongcheng Machinery Co,Ltd

|

Gold Index: 18883

You are here: home > 2-Years Warranty Stone Crusher For Road And Airport Project

2-Years Warranty Stone Crusher For Road And Airport Project

| Price: | 1000.0~10000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

PE600*900

Production Capacity:

100sets/mouth

Delivery Date:

7~15 days after payment

Type:

Crusher

Warranty:

1 year

Means of Transport:

Ocean,Land

Packing:

Export standard

Application:

Ore

Brand Name:

ZHONGCHENG

Detailed Product Description

1. Stable and long span life

2. Easy to adjust

3. Reliable operation.

4. Easy maintenance.

5. No polluti

hina Leading Stone Crusher For Quarry Site

Contact with Windy +0086-13526578789

1.Stone crusher's Introduction:

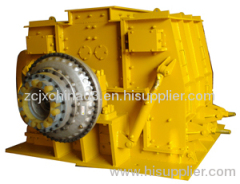

Stone crusher's main structures are made up of rack, eccentric shaft, the pulley, flywheel, moving jaw, side shield, elbow board, elbow, the rear plate, transfer gap screw, spring reset, fixed plate and the activities of jaw board, Bracket also plays an important role in insurance.

WELDED STONE CRUSHER

2.Stone crusher's working principle:

The broken type of this jaw stone crusher is Qu dynamic squeeze-type. the machine's leather of belt and wheel are driven by the electric motor, then the movable jaw begins to move up and down by the eccentric shaft, when the movable jaw moves from bottom to top, the angle between fixed jaw and movable jaw becomes bigger, then promotes the active board close to the fixed board. At the same time material to be extruded, molded, multi-roller crusher, etc.

CAST STEEL STONE CRUSHER

3.Stone crusher's performance characteristics:

1. Broken deep cavity, there is no dead zone, Increased the feed capacity and output

2. Large broken ratio, Uniform particle size of the products.

3. Gasket-style nesting adjustment device, Convenient and reliable, large adjustment range, Increase the flexibility of the equipment

4. Lubrication system is safe and reliable, Convenient replacement of parts, small maintenance workload.

5. Simple structure, work reliable, low operating costs.

6. energy saving equipment, System can save energy more than one half.

7.large adjustment range of the nesting, can meet different users' requirements.

Installation Of Stone Crusher Plant

4. Technical parameters of stone crusher:

Type | Feed openning (mm) | Max.feeding size(mm) | Adjusting range of feed opening(mm) | Handling capacity(t/h) | Rotation speed of eccentric shaft (r/min) | Motor power (kw) | Total weight (t) | Overall dimensions(L×W×H)(mm) |

PE150×250 | 150×250 | 120 | 10-40 | 1-3 | 250 | 5.5 | 0.6 | 720×660×850 |

PE250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300×1090×1270 |

PE400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

PE-500×70 | 500×750 | 425 | 50-100 | 4-110 | 275 | 55 | 12 | 1980×2080×1870 |

PE600×900 | 600×900 | 500 | 75-160 | 50-180 | 250 | 55-75 | 17 | 2190×2206×2300 |

PE750×1060 | 750×1060 | 630 | 80-140 | 115-330 | 250 | 110 | 29 | 2660×2430×2800 |

5.Remark:

1.The marked technical parameters of the machine are by the standard of middle-hard stone pile ratio 1.6t/m3.

2.The feeding quality,feeding shape and grain size etc elements will affects the machine`s processing ability.

Related Search

Stone Crusher

Crusher Stone

Jaw Stone Crusher

Stone Mobile Crusher

Stone Powder Crusher

Led Project

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Henan Zhongcheng Machinery Co,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhengzhou

Province/State: Henan

Country/Region: China (Mainland)

.gif)